Services and Capabilities

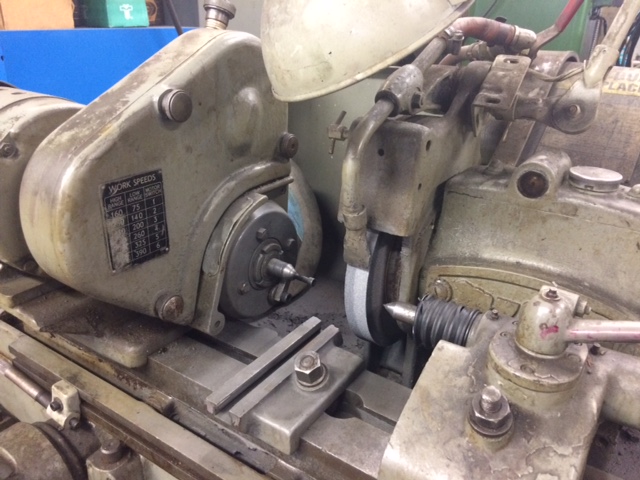

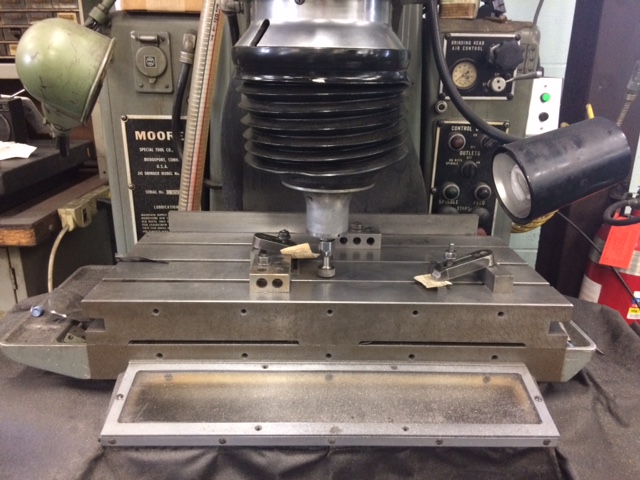

Machining Services

Applications We Support:

We use our machining expertise to create cutting edge tooling and part solutions for our customers. Our machining capabilities extend beyond the basics we have experience in tool prototyping, part design, part redesign, tool and part build, and inspection. We support major local and international manufactures by providing them with customized tooling solutions.